From Mechanic to Robot Tech: Transitioning into Robotic Maintenance Careers

The rapid expansion of automation across manufacturing, logistics, healthcare, and energy has created a new demand for skilled professionals who can maintain and troubleshoot robotic systems. For experienced mechanics, industrial technicians, and maintenance professionals, transitioning into robotic maintenance careers is a natural and highly achievable next step.

If you already understand machinery, diagnostics, and preventive maintenance, you are closer to becoming a robot tech than you may realize.

Why Mechanics Are a Strong Fit for Robotic Maintenance

Robotic systems are built on the same mechanical principles found in traditional equipment. Motors, bearings, belts, gearboxes, and pneumatic components are still at the core—automation simply adds controls, sensors, and software.

Mechanics bring valuable strengths to robotic maintenance roles, including:

-

Hands-on troubleshooting experience

-

Understanding of mechanical motion and wear points

-

Preventive maintenance discipline

-

Comfort working with complex machinery

-

Strong safety awareness

These skills form the backbone of robotic maintenance and significantly shorten the learning curve.

What Changes When You Move into Robotics

The main shift from mechanical maintenance to robotic maintenance is learning how automation and controls interact with physical systems.

Key new areas include:

-

Programmable logic controllers (PLCs)

-

Sensors, encoders, and vision systems

-

Servo motors and variable frequency drives

-

Human-machine interfaces (HMIs)

-

Automated safety systems

While these may sound intimidating, mechanics already diagnose problems logically—robotics simply adds data and software to that process.

Skills Mechanics Should Add to Transition Successfully

To move into robotic maintenance, mechanics should focus on building complementary skills rather than starting over.

High-value skills include:

-

Basic electrical troubleshooting

-

Reading control schematics and ladder logic

-

Understanding automation workflows

-

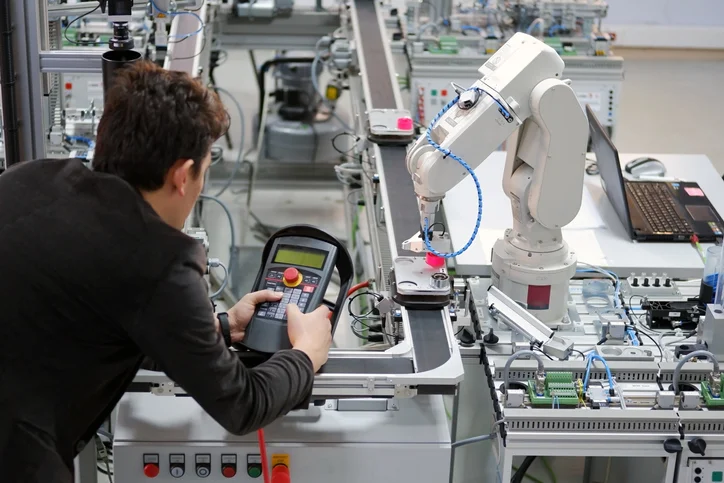

Using diagnostic software and teach pendants

-

Performing system calibrations and resets

Even limited exposure to these areas can make a mechanic competitive for automation-focused roles.

Training and Learning Options for Career Transition

Many mechanics transition into robotic maintenance through flexible learning paths:

-

On-the-job cross-training within automated facilities

-

Community college automation or mechatronics programs

-

Employer-sponsored technical training

-

Online PLC and robotics courses paired with hands-on practice

Employers often prefer candidates who combine mechanical expertise with growing automation knowledge.

Tools and Technologies You’ll Encounter

Robotic maintenance technicians commonly work with automation platforms from companies such as Allen-Bradley and Siemens, as well as robotic systems manufactured by FANUC, ABB, KUKA, and Yaskawa.

Familiarity with just one platform can open doors, and skills often transfer easily between systems.

Entry Points for Mechanics Moving into Robotics

Mechanics often transition into robotic maintenance through roles such as:

-

Industrial maintenance technician with automation exposure

-

Automation or controls technician trainee

-

Robotic maintenance technician

-

Facilities automation technician

-

Reliability or equipment specialist

These roles allow mechanics to expand their technical scope while building robotics experience.

Salary Growth and Career Advancement

Robotic maintenance careers typically offer higher pay than traditional mechanical roles due to their technical complexity and demand. As mechanics gain automation experience, earning potential increases significantly.

Advancement opportunities include senior robotic technician, controls specialist, automation engineer, or maintenance leadership roles.

Long-Term Career Stability

Automation continues to expand across industries, making robotic maintenance a resilient and future-focused career path. Mechanics who adapt and add automation skills position themselves for long-term stability, increased responsibility, and stronger job security.

Final Perspective

Transitioning from mechanic to robot tech is not a career reset—it’s a progression. Mechanical expertise remains essential in automated environments, and those who combine hands-on experience with automation knowledge are among the most valuable professionals in today’s workforce.

For mechanics willing to learn new technologies, robotic maintenance offers a practical, rewarding, and sustainable career path in an increasingly automated world.